News

PWM vs ESC: Which Is Best for Motor Control

You want the best way to control your motor. The answer depends on your motor type and your goal. PWM is good for simple brushed motors. ESCs work better with brushless motors in hard jobs. You can find PWM and ESC in drones, RC cars, fans, and disk drives. They are also in industrial servos, hybrid cars, and strong gearmotors. When you look at pwm vs esc, pick what fits your motor and use. This will give you the best results.

Key Takeaways

- PWM works well for simple brushed motors. It is cheap and easy to use.

- ESCs are needed for brushless motors. They give better speed and direction control.

- Use PWM for small projects. Use ESCs for things like drones and RC cars.

- Knowing how hard and expensive each is helps you pick the best motor control.

- Always use the right controller for your motor. This keeps it working well and safe from harm.

What Is Pulse Width Modulation (PWM)?

How PWM Works

Pulse width modulation helps you change how fast a motor spins. It does this by sending quick electrical pulses to the motor. The size of each pulse changes how much power the motor gets. If the signal stays on longer, the motor gets more voltage and goes faster. If the signal is on for less time, the motor slows down. The duty cycle tells you how long the signal is on in each cycle. For example, a 50% duty cycle means the motor gets half the full voltage.

PWM turns the signal on and off very fast. A microcontroller like Arduino or STM32 makes the PWM signal. A MOSFET or BJT acts like a switch for the motor’s current. You need a flyback diode to keep your circuit safe from voltage spikes. The main things you need for basic PWM motor control are:

- Microcontroller to make the PWM signal

- MOSFET or BJT for switching

- Flyback diode for safety

- DC motor

- Power supply

- Gate resistor (optional)

- Snubber circuit (optional)

Tip: Changing the duty cycle helps you set the motor speed without wasting power.

PWM Applications

You can find pwm in lots of things at home and in factories. It helps control how fast fans and motors spin. You can also use pwm to dim LED lights smoothly. In robots, pwm lets you control motor speed for better moves. Factories use pwm to control motor speed and heat. You also see pwm in battery chargers and audio systems.

Here are some ways people use pwm:

- Motor speed control in robots and machines

- Dimmable LED lighting systems

- Electric fan speed adjustment

- Temperature control in heaters

PWM gives you good and exact control in many electronics. It helps save energy and makes your projects work better.

What Is an Electronic Speed Controller (ESC)?

How ESCs Work

An electronic speed controller helps you manage how fast and in which direction your motor spins. You use it as a bridge between your battery and your motor. The electronic speed controller takes signals from your transmitter or flight controller. It reads a pulse width modulation (PWM) signal that tells it how fast you want the motor to go.

Here is how an esc works step by step:

- The esc receives a PWM signal from your controller. This signal carries your speed command.

- The esc reads the signal and changes it into strong electrical pulses for your motor.

- It uses high-frequency switching with MOSFETs to control the voltage and current.

- For brushless motors, the esc creates a three-phase output. It switches the current through the motor windings at the right time to make a rotating magnetic field.

- The spinning field moves the rotor’s magnets, making the motor turn.

- The esc uses sensorless or sensor-based feedback to keep the motor running smoothly.

You can find advanced brushless esc models like the XC-BLDC E3 PRO ESC. This esc gives you strong power and smooth control for RC cars and trucks. It supports high voltage and current, so you get reliable performance even in tough conditions. You can install and calibrate escs easily with clear instructions from XC-BLDC.

Tip: If you want to avoid troubleshooting common esc issues, always follow the setup guide and check your connections.

ESC Applications

You use electronic speed controllers in many places. They help you control motors in RC vehicles, drones, and even industrial machines. Here is a table showing common uses:

| Application Type | Description |

|---|---|

| Multirotor Drones | You get stable flight and smooth movement by controlling motor speed. |

| Fixed-Wing Aircraft | You manage thrust for safe takeoffs and landings. |

| Ground Vehicles | You control acceleration and braking for RC cars and trucks. |

| Marine Systems | You run motors quietly and efficiently in boats and underwater vehicles. |

You also see escs in electric bikes, scooters, and robots. Brushless esc models like the XC-BLDC E3 PRO ESC work well in RC cars, drones, and industrial equipment. XC-BLDC offers escs for heavy-lift drones and specialized machines. These controllers give you precise motor control and long-lasting performance.

If you want to get the best results, choose an electronic speed control system that matches your motor and project needs.

PWM vs ESC: Key Differences

Control and Precision

You need to understand how control works in both systems. PWM lets you change the speed of a motor by adjusting the duty cycle. You send quick pulses to the motor, and the length of each pulse decides how much power the motor gets. ESCs use PWM signals too, but they take your command and switch high-current digital switches called FETs. This gives you better control over the motor, especially with brushless motors.

When you look at pwm vs esc, you see that ESCs offer more precise control. ESCs can manage speed and torque with software, so you get smoother throttle response. In RC cars, ESCs let you control speed and direction with great accuracy. PWM alone can cause velocity ripple because of load changes, but ESCs reduce this problem by using higher frequencies and smart feedback.

Note: ESCs give you better control and precision, especially when you need smooth starts and stops.

Compatibility

You must match your motor type with the right control system. PWM works best with simple brushed motors. ESCs are made for both brushed and brushless motors, but you need a brushless ESC for three-wire brushless motors. The table below shows which system fits each motor:

| Motor Type | ESC Type | Description |

|---|---|---|

| Brushed | Brushed ESCs | Designed for traditional brushed motors, usually with two wires. Reliable and common in entry-level projects. |

| Brushless | Brushless ESCs | Made for high-performance brushless motors, usually with three wires. Offers better efficiency and smoother control. |

When you compare pwm vs esc, you see that ESCs are needed for brushless motors. PWM alone cannot drive a brushless motor because it cannot create the rotating magnetic field needed.

Complexity

You want your project to be easy to build and maintain. PWM is simple. You only need a microcontroller, a switch, and a few basic parts to control a brushed motor. ESCs add more complexity. They have more parts inside, like sensors and software, to control the motor. ESCs can handle noise and errors better, which helps in bigger projects with many motors.

- PWM is easy to set up and use for small projects.

- ESCs are more complex but give you advanced control features.

- ESCs can manage multiple motors and handle tough environments.

When you look at pwm vs esc, you must decide if you want simple control or advanced features.

Cost

You need to think about your budget. PWM controllers cost less. You can find basic PWM chips for around $7. ESCs cost more, especially for high-performance or industrial models. Hobby ESCs have a wide price range, and industrial ESCs can cost $170 to $230.

| Type | Price Range |

|---|---|

| PWM Controller | $7 |

| ESC (Hobbyist) | Varies by brand |

| Industrial Drives | $170 – $230 |

When you compare pwm vs esc, you see that PWM is cheaper for simple jobs. ESCs cost more but give you better control and features.

Performance

You want your motor to run well and save energy. PWM systems work best at higher speeds. At low speeds, you get more losses and less efficiency. ESCs keep the motor running smoothly under heavy loads. ESCs can control the motor amps better, so you get strong torque and stable speed.

- PWM systems lose efficiency at low duty cycles.

- ESCs keep high performance even when you push your motor hard.

- ESCs help you get the most out of your battery and motor.

When you look at pwm vs esc, you see that ESCs win in tough jobs and high-performance projects. ESCs give you better control, efficiency, and reliability.

Tip: For brushless motors and demanding tasks, choose an ESC for the best control and performance.

Pros and Cons

PWM Pros

You get many benefits when you use PWM for motor control.

- You save money because PWM controllers cost less than other options.

- You enjoy high efficiency, often reaching 80-90%, which helps you use less energy.

- You can control motor speed with precision, making your projects easier to manage.

- You extend the life of your motor by reducing wear and tear.

- You find PWM simple to set up. You do not need complex circuits or extra parts.

- You can use PWM in many applications, from fans to robots.

Tip: If you want a straightforward solution for brushed motors, PWM gives you reliable results without breaking your budget.

PWM Cons

PWM does have some limits, especially with brushless motors.

- You may notice current ripple, which means the current goes up and down each cycle.

- High current ripple increases RMS current, causing extra heat and energy loss.

- You might see more eddy current losses at higher speeds, which can lower efficiency.

- PWM alone cannot drive brushless motors because it cannot create the rotating magnetic field they need.

ESC Pros

ESCs offer advanced features for motor control.

- You can change the direction of your motor easily, which is important for RC cars and drones.

- You get safety features like overcurrent protection, thermal protection, and emergency stop.

- You protect your motor and battery from damage with low voltage cutoff and stall detection.

- You improve motor performance and lifespan by using the right ESC.

- You enjoy smooth starts and stops, avoiding jerky movements.

Note: ESCs give you more control and safety, especially when you work with brushless motors or demanding projects.

ESC Cons

ESCs come with a few challenges.

- You may face overheating if you do not match the ESC with your motor or if you push it past its current rating.

- You might experience signal loss, which can make your motor act unpredictably.

- You need to calibrate your ESC to get the best response from your motor.

- You must watch out for power surges, as sudden spikes can damage your ESC if your battery voltage is not compatible.

Always check your ESC setup and follow the instructions to avoid common problems.

Choosing the Right Motor Control

By Motor Type

First, look at what kind of motor you have. Brushed motors can use simple ESCs or just PWM to turn on and off or change speed. Brushless motors need special ESCs to work right and run smoothly. Some new ESCs have Battery Eliminator Circuits (BEC). BECs help keep the voltage steady for your receiver and servos.

- Brushed motors work with basic ESCs or PWM for simple control.

- Brushless motors need advanced ESCs for good timing and control.

- Many ESCs have BECs to give safe, steady power.

To get the best results, match your pwm escs to your motors. This helps you avoid problems and makes everything work well.

By Project Needs

Think about what your project needs. If you want to control speed for fans, robots, or small cars, PWM is a good choice. Many motor boards use PWM, so you do not need hard wiring or coding.

For drones, RC cars, or big machines, you need more control. ESCs help you manage torque and speed very well. You only need one wire from your autopilot to the ESC. This keeps your setup neat and easy.

- Use PWM for simple speed control in easy projects.

- Pick ESCs for drones, RC cars, or big machines that need exact control.

- Brushless motors need ESCs to turn your commands into the right current.

If your project needs lots of power or special features, match your pwm escs to the right motors. This helps you save energy and get better results.

By User Experience

Think about how much you know. If you are new, PWM is easy to use. You can make simple circuits and control speed with just a few parts. ESCs need more setup and tuning, but they give you extra features and safety.

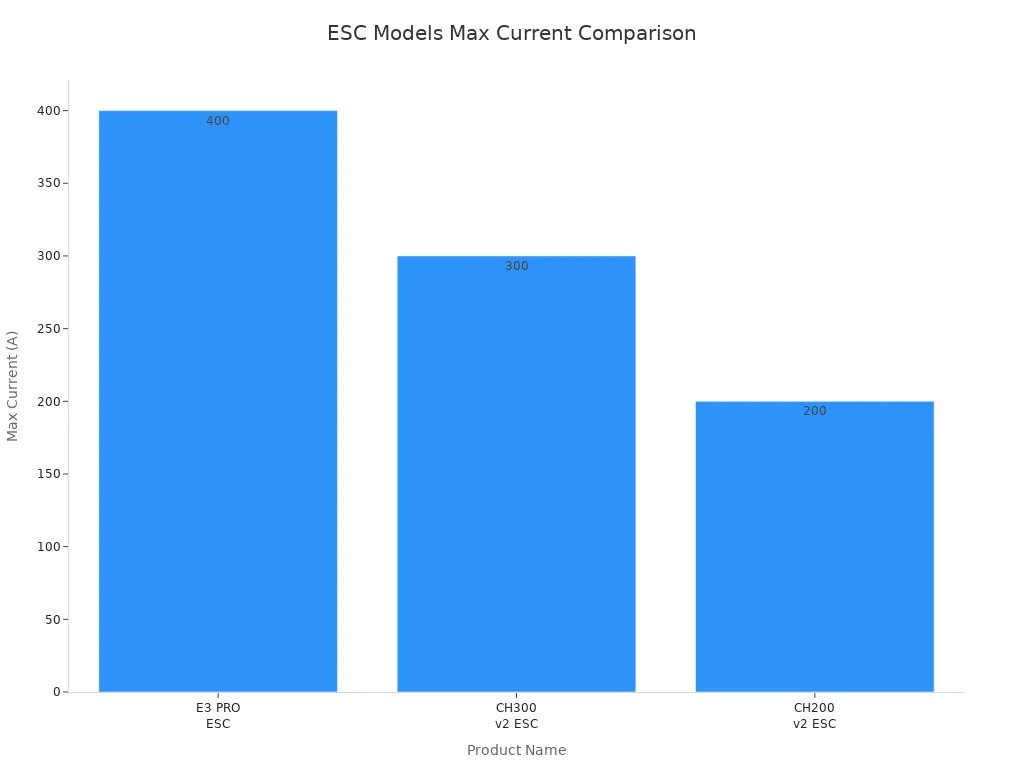

If you work on hard projects, look at pro ESCs. XC-BLDC has the E3 PRO ESC for RC cars and trucks. This ESC can handle up to 400A and works with 6-12S LiPo batteries. It is waterproof, has two fans, Bluetooth, and works with both sensored and sensorless motors. For drones and big machines, you can use the CH300 v2 ESC or CH200 v2 ESC. These work with high voltage and tough jobs.

| Product Name | Max Current | Voltage Range | Best For | Key Features |

|---|---|---|---|---|

| E3 PRO ESC | 400A | 6-12S LiPo | RC Cars (racing, bashing) | Waterproof, dual fans, Bluetooth, sensored/sensorless support |

| CH300 v2 ESC | 300A | 12-24S LiPo | Heavy-lift drones, UAVs | High voltage, advanced tuning, cooling fans |

| CH200 v2 ESC | 200A | 12-24S LiPo | Off-road RC cars | Rugged, waterproof, heat resistant |

Tip: If you want your RC car, drone, or machine to be strong and last long, pick an ESC from XC-BLDC. These controllers give you lots of power, smooth moves, and good reliability.

You have learned the main differences between PWM and ESC. PWM is good for simple brushed motors. ESCs help you control brushless motors and hard jobs. You should pick based on your motor and project.

- Use PWM with brushed motors in small quadcopters to save money.

- Heavy drones need brushless motors and ESCs for strong power.

- Always check your ESC firmware and sensors to avoid mistakes.

- Smart robots and HVAC systems use good motor control for better work.

- New ideas focus on smart control, saving energy, and using IoT.

Tip: Choose the right motor control for your project goals. Look for guides and resources to learn more about PWM and ESC systems.

FAQ

What is the main job of a motor controller?

You use a motor controller to change how fast or slow your motor spins. It helps you start, stop, and control the direction of your motor. This makes your project work the way you want.

Can you use PWM to control any type of motor?

You can use PWM to control a brushed motor. If you have a brushless motor, you need an ESC. PWM alone cannot make a brushless motor spin because it cannot create the right signals for that motor.

Why do drones need special motor controllers?

Drones use brushless motors for strong power and long life. You need a special ESC to control each motor. The ESC helps your drone fly steady and respond quickly to your commands.

How do you pick the right motor controller for your project?

First, check what kind of motor you have. If you use a brushed motor, PWM works well. For a brushless motor, choose an ESC. Think about your project’s needs and how much control you want over your motor.

What happens if you use the wrong controller with your motor?

If you use the wrong controller, your motor may not work or could get damaged. Always match your controller to your motor type. This keeps your motor safe and helps your project run smoothly.