News

Do You Need an ESC for a Brushless Motor?

You need an ESC if you want your brushless motor to work. Brushless motors do not have brushes or a commutator. When you apply direct current to a winding, the rotor stays still, and too much current can damage the winding. The electronic speed control switches the current in the motor windings at the right time using a controller. This action creates the rotating magnetic field that makes the motor spin. The ESC protects the motor, limits current, and controls speed. High-performance ESCs like the XC-BLDC E3 PRO ESC show how important a good controller is for brushless setups.

Key Takeaways

- Brushless motors need an ESC to work. They do not have brushes or a commutator to switch current.

- The ESC controls how fast the motor spins. It also controls which way the motor turns. The ESC keeps the motor safe by watching current and temperature.

- The ESC uses electronic commutation. This makes a spinning magnetic field. The field helps the motor turn smoothly and work well.

- You must pick an ESC that matches your motor and battery. The voltage and current ratings should be the same for safe use.

- Good ESCs, like the XC-BLDC E3 PRO, give better control. They also protect the motor and help it work well in tough jobs.

ESC for Brushless Motors

Why ESC Is Needed

You need an ESC for brushless motors because they do not have brushes or a commutator. Brushed motors use brushes and a commutator to change current direction as the rotor moves. Brushless motors need an ESC to do this job. The ESC is like the brain of the system. It sends timed bursts of current to the motor windings. This makes a spinning magnetic field that keeps the rotor turning.

- Brushless motors need timed bursts of current to different windings.

- The ESC makes three-phase AC power and changes timing based on rotor position.

- Sensors like Hall effect sensors or back EMF help find the rotor’s position.

- The ESC gives exact timing and switching, which is needed for brushless motors.

- ESCs also control speed, can reverse direction, and protect the motor.

A high-performance ESC, like the XC-BLDC E3 PRO ESC, gives steady power and better control. This controller works with many voltages and can handle high current. It is great for tough RC uses.

Tip: Always use an ESC that matches your motor’s needs for best results and safety.

How Brushless Motors Work

Brushless motors have magnets on the rotor and coils on the stator. The controller powers the stator coils in a set order. This makes a spinning magnetic field. The field pushes the rotor magnets, making the rotor spin. The controller uses sensors or back EMF to know where the rotor is and when to switch the current.

| Aspect | Brushed Motor | Brushless Motor |

|---|---|---|

| Commutation Method | Brushes and a commutator ring switch current direction as the motor turns | Sensors and an electronic controller switch current direction electronically |

| Rotor and Stator | Rotor has windings; stator has magnets | Rotor has magnets; stator has coils powered by the controller |

| Current Flow | Brushes touch the commutator to send current to the rotor | Controller powers stator coils based on rotor position |

| Rotation Generation | Magnetic field in rotor windings pushes against stator magnets to spin the rotor | Spinning magnetic field in stator coils pushes rotor magnets to spin the rotor |

| Maintenance | Brushes wear out from rubbing and need to be replaced | No brushes means less wear and a longer life |

| Efficiency & Noise | Lower efficiency and more noise because of brushes | Higher efficiency and less noise because there are no brushes |

| Control Complexity | Simple speed and torque control by changing current direction | Needs a controller for exact timing and coil switching |

Brushless motors need a controller for exact timing and switching. This setup gives you better efficiency, less noise, and a longer life than brushed motors.

Electronic Commutation

Electronic commutation takes the place of the mechanical switching in brushed motors. The ESC for brushless motors uses sensors or back EMF to find the rotor’s position. It then switches current through the stator windings in a set order. This makes a spinning magnetic field that turns the rotor.

- The ESC finds the rotor’s position with Hall effect sensors or back EMF.

- It switches current through the stator windings in six steps, powering two windings at once.

- The ESC uses PWM to control how much voltage goes to the motor, changing speed and torque.

- The ESC changes DC power into three-phase AC using MOSFETs in an H-bridge.

- Sensor control gives steady feedback, while sensorless control guesses rotor position from back EMF.

Electronic commutation has many good points:

- You get better efficiency because there are no brushes to wear out.

- The motor is quieter and lasts longer.

- You can seal the motor to keep out dust and water, so it is more reliable.

If you want these benefits, try the XC-BLDC E3 PRO ESC. This ESC for brushless motors has advanced features, strong performance, and is easy to install. You can find more choices at www.xc-esc.com.

Electronic Speed Control Functions

Power and Speed Regulation

You use an esc to change how fast your brushless motor spins. The esc gets signals from your remote or flight controller. It uses pwm to decide how much power the motor gets. When you push the throttle up, the esc sends longer pwm pulses. This makes the motor spin faster. If you lower the throttle, the esc sends shorter pulses. That slows the motor down.

Inside the esc, there is a microprocessor and MOSFET switches. The microprocessor reads your commands and sets the timing for pwm signals. MOSFETs are fast switches. They turn the power on and off very quickly. This helps the motor speed up smoothly and gives you good control.

The esc changes DC power from your battery into three-phase AC power. This lets the controller manage speed, direction, and braking. Many escs have a Battery Eliminator Circuit (BEC). The BEC powers your receiver and servos from the main battery.

Here is a table that lists what an esc does:

| Primary Function | Description |

|---|---|

| Power Conversion | Changes DC battery power into controlled 3-phase AC for the motor. |

| Speed Control via PWM | Uses pwm to make the motor speed up or slow down. |

| Signal Interpretation | Reads throttle signals and uses a microprocessor to process them. |

| Current Regulation | Uses MOSFETs to control how much current goes to the motor. |

| Direction Control | Switches phase order to change which way the motor spins. |

| Rotor Position Detection | Finds rotor position for correct phase switching. |

| Additional Features | Adds braking, acceleration control, and BEC for powering receiver and servos. |

| Firmware Control | Runs special software for exact speed control and power delivery. |

The XC-BLDC E3 PRO ESC works with many voltages and can handle lots of current. It gives you steady power and smooth throttle control, even when you use it for tough RC jobs.

Note: Always pick an esc that matches your motor and battery for safe use.

Buy XC-BLDC ESC Products{: .btn}

Protection Features

Your esc keeps your motor and electronics safe from harm. High currents can make things too hot, so escs use heat sinks and thermal sensors to cool down. Some escs have fans to help get rid of extra heat.

Modern escs have many ways to protect your system:

- Overcurrent protection stops power if the current gets too high.

- Overvoltage protection sends extra voltage away to keep things safe.

- Thermal protection checks temperature and shuts down if it gets too hot.

- Voltage compatibility checks make sure the esc matches your battery.

- Capacitors soak up power surges and cut down on noise.

- Heat sinks and fans help keep the esc cool when you use it a lot.

These features help your esc last longer and keep your motor working well. The XC-BLDC E3 PRO ESC has strong heat control and tough protection, so it is great for high-power setups.

Here is a table that shows how esc protection works:

| Protection Type | Working Principle | Devices/Methods Used |

|---|---|---|

| Overcurrent | Finds high current and stops power to protect the circuit. | Fuses, circuit breakers, current sensing ICs. |

| Overvoltage | Finds high voltage and sends extra to safe places. | TVS diodes, varistors, voltage limiters. |

| Thermal Protection | Checks temperature and cuts power if it gets too hot. | Thermal relays, PTC thermistors, heat sinks, cooling fans. |

Tip: Pick an esc with strong protection to keep your motor safe.

Signal Processing

Your esc uses signal processing to help your motor run smoothly. It reads throttle signals from your radio or flight controller. The esc uses pwm to control how much power the motor gets. This gives you good speed control and saves power.

Sensorless escs find rotor position using back EMF. Sensored escs use Hall effect sensors for better feedback. Some escs let you change settings like braking, acceleration, and voltage cutoffs.

The esc parts work together to process signals fast. The microprocessor reads your input and changes pwm pulses. MOSFETs turn power on and off to control speed, direction, and braking. Advanced escs like the XC-BLDC E3 PRO ESC can use digital protocols like DShot. This gives you quick and steady communication with your remote.

- ESC reads throttle signals to control the motor.

- PWM makes speed changes smooth and saves power.

- Sensorless and sensored types give different feedback and control.

- Programmable settings let you set up speed control for your needs.

Note: Good signal processing in your esc helps your motor work well and respond quickly.

Brushed vs. Brushless Motor Systems

Key Differences

You may wonder how these two motor systems are different. Brushed motors use carbon brushes and a commutator to switch current. This setup makes the motor spin. The brushes rub against the commutator. This causes friction, heat, and wear. You have to change the brushes often. It can be messy and take time. Brushless motors work in another way. They use a controller to move current with electronics. Permanent magnets and windings work together without touching. This means there is less friction and less noise.

Brushless motors last much longer than brushed motors. They can run for tens of thousands of hours. Brushed motors usually last only a few thousand hours. Brushless motors give more torque and faster acceleration. They are more efficient and run smoother. Brushed motors cost less and are good for simple jobs. But they do not last as long or work as well as brushless motors.

Here is a table that shows the main differences:

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Construction | Brushes and commutator create friction and wear | Electronic controller and magnets, no brushes |

| Efficiency | Lower, energy lost to friction | Higher, minimal energy loss |

| Maintenance | Frequent brush replacement needed | Almost maintenance-free |

| Torque | Smooth at low speeds | High torque, fast acceleration |

| Noise | Louder due to brush contact | Quieter operation |

| Lifespan | Shorter, 1,000–3,000 hours | Longer, up to 100,000 hours |

| Cost | Lower upfront cost | Higher upfront cost |

Tip: Pick brushless motors if you want high performance and long life.

ESC Requirements

It is important to know why an ESC is needed for brushless motors. Brushed motors use brushes to switch current. You can run them straight from a battery. You do not need a controller unless you want better speed control. Brushless motors do not have brushes or a commutator. They need electronic commutation, which only an ESC can do.

If you try to use a brushless motor without an ESC, it will not spin. The magnetic fields will not switch at the right time. You could break the motor. The ESC acts like the brain. It switches current through the windings and controls speed and direction. It also adds protection. You get smooth running, better efficiency, and safety.

- Brushed motors: ESC is optional, direct power works for simple use.

- Brushless motors: ESC is needed, controller handles all functions.

- Without an ESC, brushless motors cannot run and may get damaged.

Note: Always use the right ESC with your brushless motor to keep it safe and working well.

Buy XC-BLDC ESC Products{: .btn}

Choosing an Electronic Speed Controller

Compatibility Factors

When you pick an electronic speed controller, it must match your brushless motor and what you want to do. First, check the motor’s kV rating and the esc’s amp rating. The esc needs to handle the current your motor uses, even when working hard. You also have to check if the battery voltage matches the esc. Make sure the esc works with your battery type, like LiPo or NiMH, and has the right Low Voltage Cutoff (LVC) settings.

The esc’s size is important. It must fit inside your RC car, drone, or other device. Waterproofing and cooling help if you use it in wet or hot places. You should check the connector types too. Strong bullet connectors are good for phase wires. Sensored motors need the right harness for smooth running. Communication protocols like pwm, DShot, and DroneCAN decide how the esc talks to your flight controller or receiver. Matching connectors and protocols helps your system work well.

| Compatibility Factor | Consideration |

|---|---|

| Motor kV Rating | Match esc to motor kV for speed and torque balance |

| ESC Amperage Rating | esc rating must meet or exceed motor current draw |

| Voltage Compatibility | esc must support battery voltage range |

| Battery Type | esc should support battery chemistry and LVC settings |

| Sensored vs Sensorless ESC | Sensored for precision, sensorless for simplicity |

| Physical Size and Weight | esc must fit and not affect handling |

| Waterproofing and Cooling | Needed for wet or hot conditions |

| Brand and Reviews | Choose trusted brands for reliability |

| Maintenance | Regular cleaning and checks extend esc life |

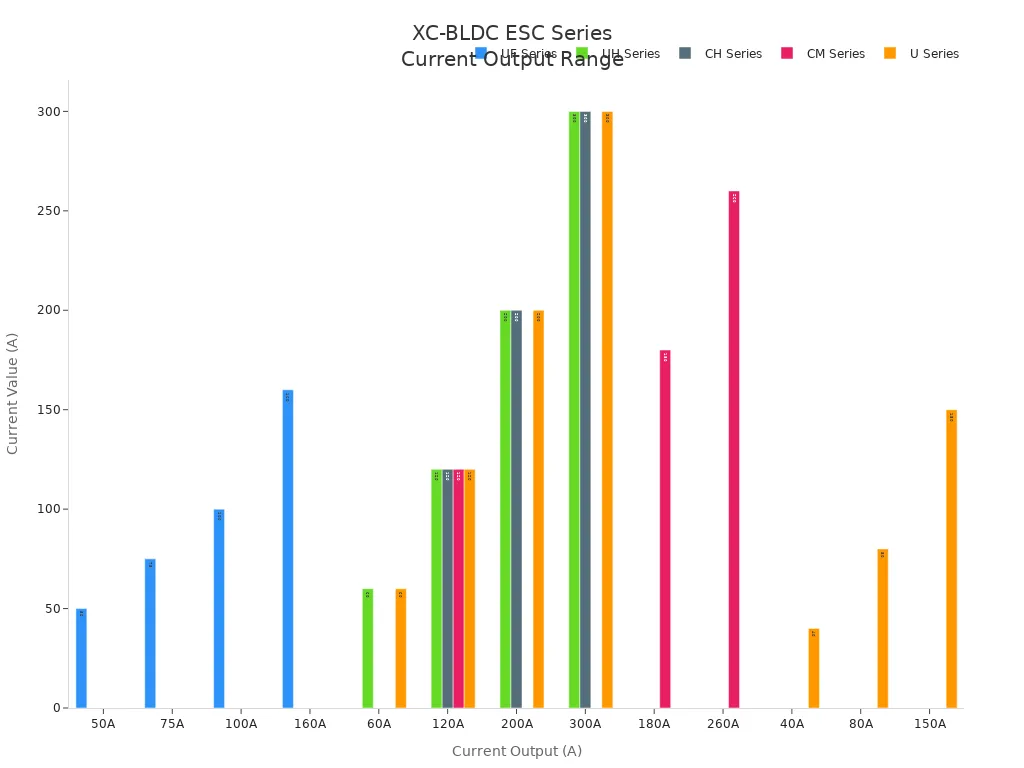

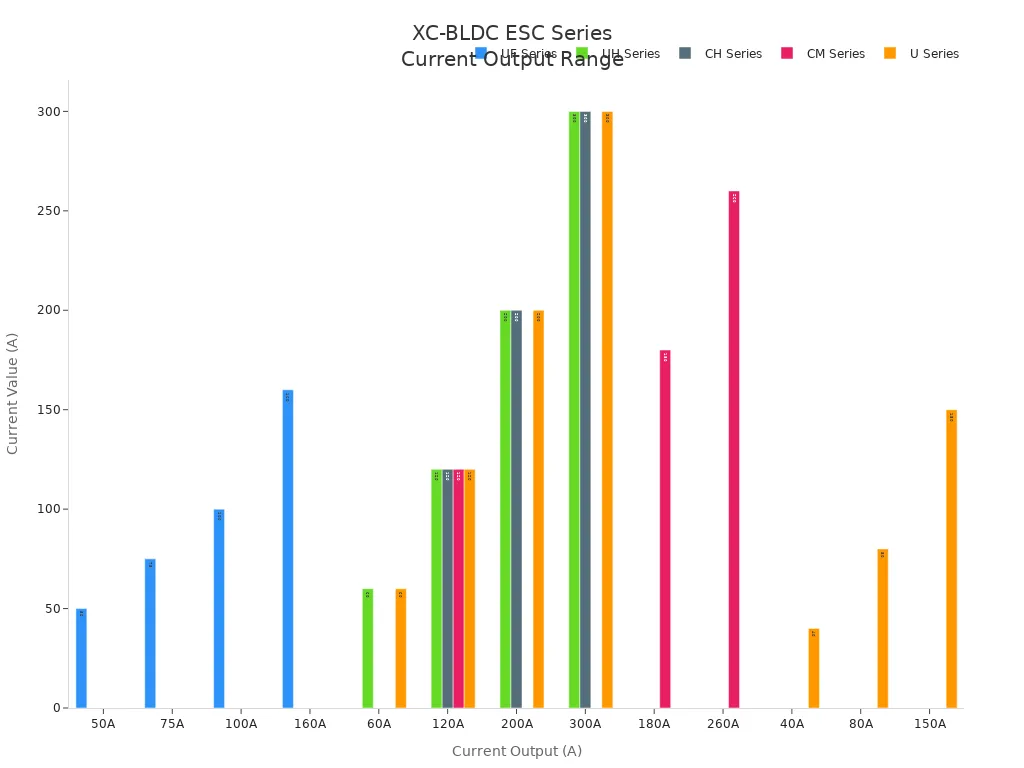

Voltage and Current Ratings

You always need to check voltage and current ratings when picking a speed controller. The esc must work with your battery’s voltage, which is shown by the number of LiPo cells, like 2S, 3S, or 6S. Using a battery with too much voltage can break the esc and be unsafe. The esc’s current rating should be higher than your motor’s top draw. This stops overheating and keeps things safe.

Escs have two current ratings: continuous and burst. The continuous rating is the safe amount the esc can handle all the time. The burst rating is for short times when you need more power. Always pick an esc with a continuous rating at least 10-20% higher than your motor needs. This helps stop shutdowns and damage.

Tip: Never use a battery or motor that goes over your esc’s voltage or current limits. Too much load can cause fires or break your esc for good.

Features to Consider

There are many kinds of electronic speed controls, each with special features. For drones, look for esc for drones with high refresh rates and light weight. These features help your drone fly better and respond faster. For RC cars, pick escs with strong brakes, waterproofing, and heat protection.

Some escs let you change settings. You can set how fast it speeds up, brakes, and the motor limits to fit your needs. Some escs show you voltage, current, and temperature as you use them. Regenerative braking can put energy back into your battery and make stops smoother. Communication protocols like pwm and DShot help your esc react fast to your commands.

XC-BLDC has many escs for different uses. You can get esc for drones, RC cars, small motors, medical tools, and pumps. Their E3 PRO ESC can handle high current and voltage, so it is great for tough RC jobs. The UF, UH, CH, and CM series work for delivery drones and big pumps. These controllers react fast, save energy, and have strong safety features.

Note: Always check the esc’s specs and make sure they match your motor, battery, and what you want to do for the best results.

Buy XC-BLDC ESC Products{: .btn}

Using an electronic speed controller helps your brushless motor work better. It keeps your motor safe and gives you smooth power. You also get more control and save energy. This stops damage and makes your motor last longer. When you pick a controller, keep these tips in mind:

- Make sure the controller matches your motor’s current and voltage.

- Choose the right kind for sensored or sensorless motors.

- Find safety features like overcurrent and thermal protection.

Brands like XC-BLDC have strong controllers for many uses.

FAQ

What happens if you run a brushless motor without an ESC?

You cannot run a brushless motor without an ESC. The motor will not spin because it needs the ESC to switch the current. You may damage the motor if you try.

Can you use any ESC with any brushless motor?

You need to match the ESC to your motor’s voltage and current ratings. Always check the specifications. Using the wrong ESC can cause poor performance or damage.

How do you know which ESC to choose for your project?

Check your motor’s maximum current and voltage. Pick an ESC that supports higher ratings than your motor needs. Look for features like waterproofing or programmability if your project requires them.

Do all brushless motors need a sensored ESC?

Not all brushless motors need a sensored ESC. Sensorless ESCs work for most uses. Sensored ESCs give smoother starts and better low-speed control, which helps in racing or crawling.

Can one ESC control multiple brushless motors?

One ESC controls one brushless motor. If you have more than one motor, you need a separate ESC for each motor.

🛒 Ready to upgrade your setup? Buy XC-BLDC ESC Products{: .btn}