News

Why Do You Need a Brushless ESC for a Brushless Motor?

Do you need an ESC for a brushless motor? Yes, you do. Brushless motors differ from brushed motors in that you can’t simply apply power and expect them to run. You need an electronic speed controller (ESC) to convert DC power into the three-phase AC signals required by your brushless motor. ESCs control the motor’s speed and direction while protecting your equipment from damage. They also help the motor start smoothly and ensure safe, reliable operation. Brushless DC motor systems with ESCs are commonly found in drones, RC cars, machinery, and medical devices. High-performance ESCs like the XC-BLDC E3 PRO ESC provide excellent control and are built to handle demanding tasks.

Key Takeaways

- You need an ESC to run a brushless motor safely and smoothly.

- An ESC helps control the motor’s speed and direction. It also keeps the motor safe from harm.

- Brushless motors need electronic switching to work. You cannot use direct battery power with them.

- Pick an ESC that matches your motor’s voltage, current, and sensor type.

- Find ESCs with safety features like overcurrent and thermal protection. This helps the motor work well and stay safe.

Do You Need an ESC for a Brushless Motor

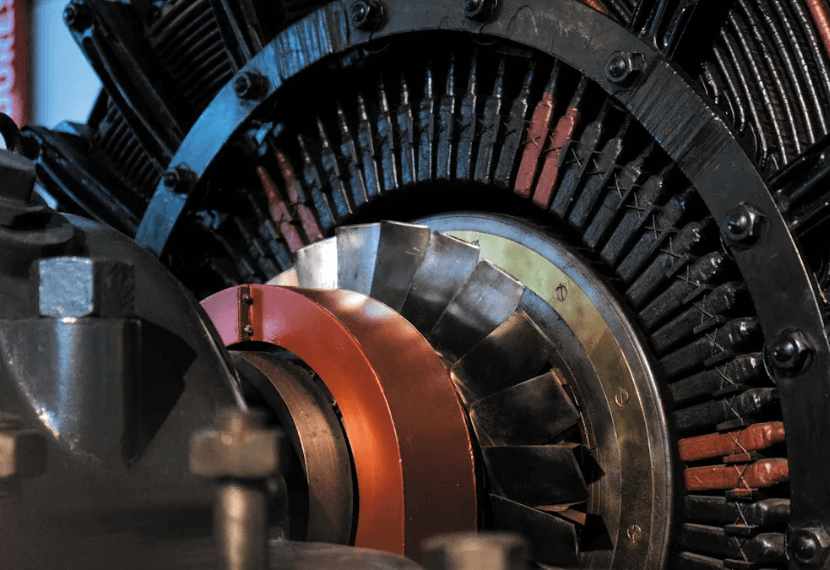

Brushless DC Motor Basics

You might wonder, do you need an esc for a brushless motor? To answer this, you first need to understand how a brushless dc motor works. The working principle of brushless motor technology is different from brushed motors. In a brushless dc motor, you find permanent magnets on the rotor and coils on the stator. The motor does not use brushes or a commutator. Instead, it relies on electronic switching to control the flow of electricity.

Here is how a brushless dc motor operates:

- The rotor contains permanent magnets.

- The stator has windings that become electromagnets when energized.

- Electronic switching creates a rotating magnetic field using a three-phase AC waveform from a DC power source.

- The interaction between the stator’s magnetic field and the rotor’s magnets causes the rotor to spin.

- The motor uses sensors or special algorithms to keep the rotation smooth and synchronized.

- Most brushless dc motors use a three-phase setup for better efficiency and control.

This design gives you high efficiency, low maintenance, and smooth operation. However, it also means you need a controller to manage the switching. That is why the question, do you need an esc for a brushless motor, is so important.

Tip: Brushless dc motors combine the best features of DC and AC motors. You get good speed control, high efficiency, and less wear because there are no brushes to replace.

Why Direct Power Won’t Work

You may think you can power a brushless dc motor by connecting it directly to a battery. This will not work. Do you need an esc for a brushless motor? Yes, and here is why.

- Brushed motors use mechanical brushes and a commutator to switch current direction. You can connect them directly to a DC power source, and they will spin.

- Brushless motors do not have brushes or a commutator. They need electronic commutation. This means you must switch the current in the stator windings in a specific sequence, based on the rotor’s position.

If you apply direct current to a brushless dc motor without an esc, several things happen:

- The rotor aligns with the magnetic field of one winding and stays still.

- The winding acts like a short circuit, causing a large current to flow.

- This high current creates heat, which can burn out the winding.

- The motor does not spin because there is no rotating magnetic field.

- No back-EMF is generated, so nothing limits the current, and damage happens quickly.

You need an esc to switch the current in the right order and create the rotating magnetic field. The esc also limits the current and protects the motor from overheating. Without it, the brushless dc motor will not work and may get damaged.

Note: Always use an esc with your brushless dc motor. This keeps your equipment safe and ensures smooth, reliable operation.

Do you need an esc for a brushless motor? The answer is clear: yes, you do. The esc is not just a helpful accessory. It is an essential part of any brushless dc motor system.

Electronic Speed Controller Functions

Speed and Power Control

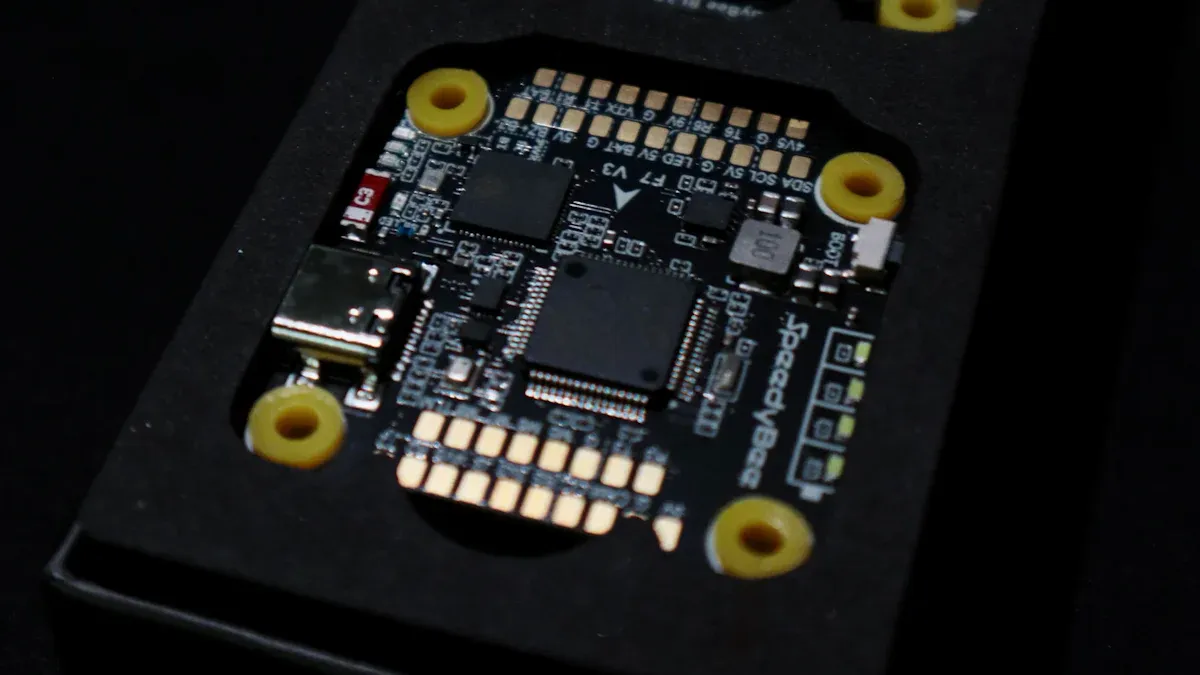

You use an electronic speed controller to change how fast and strong a brushless dc motor runs. The esc is like the brain for your motor. It turns special switches called MOSFETs on and off very quickly, sometimes 2000 times each second. This changes how much power goes to the motor. It is like flipping a light switch on and off fast to make the light dimmer. The esc gets information from sensors, like Hall Effect sensors or back-EMF, to know where the rotor is. This helps the esc send power to the right coils at the right time.

Inside the esc, a microcontroller reads your commands. It uses PWM or digital signals like DShot. The esc changes the duty cycle, which means how long the power stays on or off. This controls how much power the motor gets. This way is better than old systems that used resistors. You get smooth starts, easy speed changes, and less wasted energy.

There are different ways to control how an esc works. Here is a table with some common types:

| Control Method | Features | Typical Applications |

|---|---|---|

| Six-step square wave | Simple, fast, but can cause noise and vibration | Drones, power tools, fans |

| Sine wave control | Smooth, quiet, and efficient | Medical equipment, electric vehicles |

| Field Oriented Control (FOC) | Precise, high efficiency, advanced control | Industrial robots, automation |

These methods help the esc give your motor the best power and efficiency.

Direction and Safety

An esc does more than just change speed. It also controls which way your brushless motor spins. You can make the motor go backward by changing the order the esc powers the coils. This is important for RC cars, drones, and robots that need to move both ways.

Safety is a big part of what an esc does. New escs have many safety features to protect your motor and battery. Here are some common ones:

- Overcurrent protection stops the motor if too much current flows.

- Thermal protection keeps the esc from getting too hot.

- Low voltage cutoff stops your battery from draining too much.

- Stall detection turns off power if the motor stops moving.

- Emergency stop lets you cut power fast if something is wrong.

Some escs have even more features like current limits, limit switch cutoffs, and safe torque off. These features help stop accidents and keep your equipment working well. Using an esc makes sure your brushless dc motor system is safe, reliable, and works well.

ESC for Brushless Motors: Compatibility

Sensored vs Sensorless Motors

When you choose an esc for brushless motors, you need to know if your brushless motor is sensored or sensorless. Sensored motors have a special sensor cable that connects to the esc. This cable gives the esc information about the rotor’s position. You get smooth starts and better low-speed control with sensored setups. The esc must have a sensor port, and you must connect the wires in the right order. You cannot change the motor’s direction by swapping wires; you do it through the esc’s settings.

Sensorless motors do not have a sensor cable. The esc for brushless motors figures out the rotor’s position by reading signals from the motor itself. This works well at high speeds but can make the motor jerk or “cog” at low speeds. Sensorless setups are simpler and easier to install. Many modern escs can work with both types, but you should always check before you buy.

Tip: Sensored setups need extra care for wiring and waterproofing. Sensorless setups are easier to maintain and cost less.

Matching ESC and Motor Specs

You must match your esc to your brushless motor’s voltage and current needs. If you use the wrong esc, your motor may not run right or could get damaged. Here is a table to help you understand what to look for:

| Consideration | Explanation |

|---|---|

| Voltage Ratings | The esc must support your battery’s voltage. Using too much voltage can damage the esc. |

| Current Ratings | The esc’s current rating should be higher than your motor’s max current to prevent overheating. |

| Continuous vs Burst | Continuous current is safe for long use. Burst current is for short, high-power needs. |

For example, the XC-BLDC E3 PRO ESC works well with high-performance RC cars. It supports 6 to 12S batteries and handles up to 400A. This means you get strong power and smooth control, even when you push your RC car hard. The E3 PRO ESC also has features like braking and reverse, which are important for RC vehicles.

Brushless ESCs are not interchangeable with brushed ESCs. Brushed motors use simple DC power and mechanical switches. Brushless motors need an electronic speed controller to create three-phase AC power. Always use the right esc for your motor type to avoid problems like jerky starts, overheating, or even permanent damage.

Choosing the Right ESC

Key Features to Look For

When you pick an esc for your brushless motor, you want to match the esc’s voltage and current ratings to your motor and battery. This helps your system run smoothly and prevents overheating. Look for an esc with a waterproof and dustproof design if you plan to drive off-road or in wet places. Strong, heat-resistant materials keep the esc safe during long or hard runs. Adjustable settings let you fine-tune throttle, braking, and power delivery for your style or terrain.

Many escs offer overcurrent and thermal protection. These features stop damage if your motor draws too much power or gets too hot. Sensored escs give you smooth control at low speeds, which is great for technical driving. Compact and lightweight escs fit easily into your vehicle or drone. Trusted brands like XC-BLDC provide reliable support and clear instructions, making setup easier for you.

Tip: Always check that your esc matches your motor type and application. Using the wrong esc can cause poor performance or even damage.

Application Examples

You use different escs for different jobs. For RC cars, the XC-BLDC E3 PRO ESC stands out. It handles up to 400A and works with 6-12S batteries. This esc gives you strong power, smooth acceleration, and a waterproof build. Dual fans help keep it cool, even during tough races. Many users say the E3 PRO ESC is easy to install and offers quick throttle response. They also like its Bluetooth app control for easy tuning.

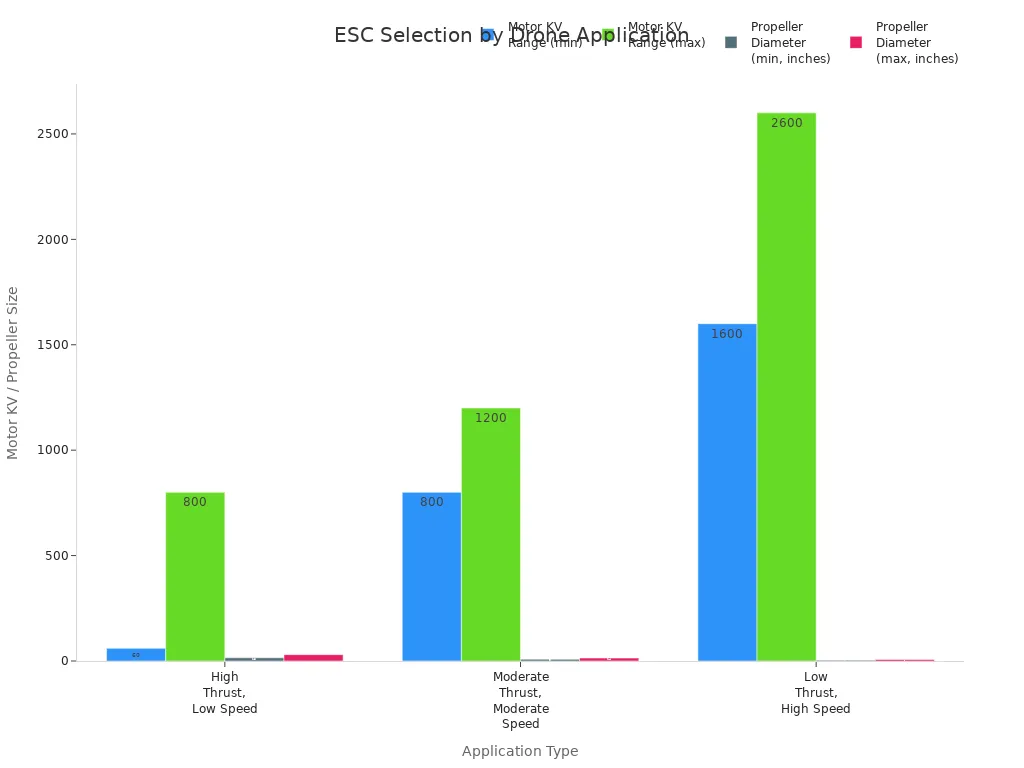

For drones, you need an esc for drones that matches your motor’s kV rating and propeller size. High-thrust drones, like delivery or agricultural UAVs, use low kV motors and large propellers. Racing drones use high kV motors and small propellers for speed. The chart below shows how motor kV and propeller size change with drone type:

XC-BLDC also makes esc for drones and esc for uavs, such as the CH300 v2 and UF series. These models support high voltages and heavy loads, making them perfect for big drones and industrial uses. The table below shows how different XC-BLDC escs fit different needs:

| Product Name | Max Current | Voltage Range | Best For | Key Features |

|---|---|---|---|---|

| E3 PRO ESC | 400A | 6-12S LiPo | RC Cars (racing, bashing) | Waterproof, dual fans, Bluetooth, sensored/sensorless support |

| CH300 v2 ESC | 300A | 12-24S LiPo | Heavy-lift drones, UAVs | High voltage, advanced tuning, cooling fans |

| CH200 v2 ESC | 200A | 12-24S LiPo | Off-road RC cars | Rugged, waterproof, heat resistant |

Customers praise XC-BLDC escs for their easy setup, strong performance, and reliability. You get clear instructions, smooth power, and stable control, even in tough conditions. Choosing the right electronic speed controller helps your motor last longer and perform better in any application.

You must always use an electronic speed controller with your brushless motor. If you do not use an ESC, the motor can get too much current. This can make the motor stop working or even break the wires inside. Your electronics could also get damaged. To keep your motor safe, follow these steps:

- Make sure the ESC voltage and current match your motor and battery.

- Check if the ESC works with sensored or sensorless motors.

- Pick an ESC that has waterproofing and thermal protection.

- Choose a brand you trust, like XC-BLDC E3 PRO ESC, for easy setup and good performance.

Professional ESCs give you strong power, settings you can change, and help from customer support. This keeps your system working well.

FAQ

What happens if you run a brushless motor without an ESC?

Your brushless motor will not spin. The motor needs an ESC to create the right signals. If you connect it directly to a battery, you risk burning out the windings and damaging your equipment.

Can you use any ESC with any brushless motor?

No, you cannot. You must match the ESC’s voltage and current ratings to your motor. Always check if your motor is sensored or sensorless. Using the wrong ESC can cause poor performance or damage.

How do you know what size ESC you need?

Check your motor’s maximum current and voltage. Choose an ESC with higher ratings than your motor’s needs. For example:

| Motor Max Current | Recommended ESC Current |

|---|---|

| 30A | 40A or higher |

| 60A | 80A or higher |

Are brushless ESCs waterproof?

Some ESCs are waterproof, but not all. Always read the product details. If you drive in wet conditions, pick a waterproof ESC like the XC-BLDC E3 PRO ESC for extra protection.

2 thoughts on “Why Do You Need a Brushless ESC for a Brushless Motor?”